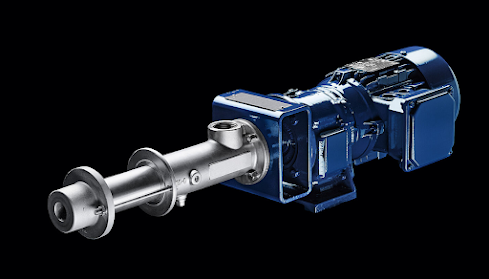

SEEPEX MDC – SANITARY METERING PUMP

SEEPEX MDC SANITARY METERING PUMP

FOR METERING APPLICATIONS REQUIRING FDA AND 3-A SANITARY-STANDARDS

SEEPEX MDC pumps are a range of hygienic metering pumps used in a variety of applications in the food, beverage, pharmaceutical and cosmetic industries to convey low to viscous media as well as shear-sensitive media. The pumps meet the highest hygienic requirements; adhering to 3-A Sanitary standards and have FDA approval.

Description of SEEPEX BNA Pump per API 676 Standard

The SEEPEX BNA pump is a high-quality positive displacement pump that conforms to the API 676 standard. Designed to handle a wide range of fluids, this pump provides reliable and efficient performance in various industrial applications. With its unique construction and innovative technology, the SEEPEX BNA pump ensures low pulsation and gentle conveyance of the pumped medium, minimizing shear forces and reducing the risk of product damage. Its modular design allows for easy maintenance and repair, while the wide range of available materials ensures compatibility with even the most challenging fluids. Overall, the SEEPEX BNA pump is an excellent choice for any application where high-quality pumping is required.

Application of SEEPEX BNA – API 676 Standard Pump

- The SEEPEX BNA pump, designed in accordance with the API 676 standard, is a preferred choice for various industrial applications. Its versatile design can handle a wide range of fluids, including abrasive and viscous media.

- With its robust construction and high-performance capabilities, the SEEPEX BNA pump is ideal for use in chemical processing, oil and gas, food and beverage, and wastewater treatment industries. The pump’s sealed design ensures leak-free operation, while its modular design provides easy maintenance and repair.

- Overall, the SEEPEX BNA pump is a reliable and efficient option for any industry that requires a powerful and durable pump solution.

Economical

Reduced costs due to inexpensive rotating unit

No vapor locking

Cavity design allows for conveyance of liquids, solids, and gases

Ease of operation

Valveless flow control for ease of operation

Performance efficiency

Low slip (internal back flow) provides performance efficiency and less wear on components

Easy maintenance

Simple and predictive maintenance due to minimal components

Residue-free cleaning

Residue-free cleaning through Clean-in-Place (CIP) continuous cleaning

Exact dosing

Additives can be precisely metered without loss. This saves costs for cost-intensive additives

Comments

Post a Comment