SEEPEX BNM – MAINTAIN-IN-PLACE PUMPSEEPEX

SEEPEX BNM – MAINTAIN-IN-PLACE PUMPSEEPEX

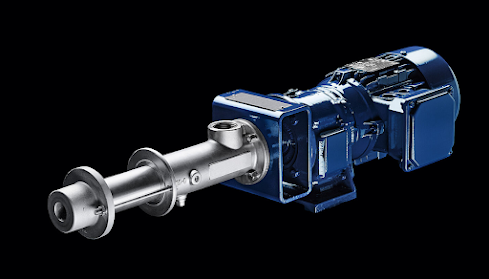

ROTOR AND DRIVE JOINT ACCESS FOR LARGE PUMPS

The BNM pump is a large standard pump equipped with smart maintenance solutions. A system known as Rotor Joint Access facilitates quick maintenance of the rotor, stator and mechanical seal via a sliding housing section. Drive Joint Access additionally allows the entire drive and coupling rod unit to easily be removed from the rear of the suction casing, thus permitting effortless maintenance of the drive-side joints.

Description of SEEPEX BNM – MAINTAIN-IN-PLACE PUMPSEEPEX

SEEPEX BNM Maintain-in-Place pump is a highly efficient and reliable pump designed for the food, pharmaceutical, and cosmetic industries. This pump is ideal for applications that require frequent cleaning or sterilization as it can be maintained in place without disassembly. With its modular design, the SEEPEX BNM pump offers easy access to all wear parts, making maintenance simple and reducing downtime. Additionally, the pump features a hygienic design with high-quality materials that meet FDA and EHEDG guidelines. Overall, the SEEPEX BNM Maintain-in-Place pump ensures the highest level of hygiene and operational reliability for your production processes.

Applications of SEEPEX BNM Maintain-in-Place Pump

The SEEPEX BNM Maintain-in-Place pump is an excellent choice for a wide range of applications in the food, pharmaceutical, and cosmetic industries. Its unique design makes it ideal for processes that require frequent cleaning and maintenance, without any need for disassembly. The pump can handle a variety of fluids, including viscous and shear-sensitive materials. This makes it suitable for use in products such as dairy, meat, sauces, creams, ointments, lotions, and toothpaste. The SEEPEX BNM pump also offers high suction capability and reliable performance, making it ideal for filling, dosing, and transfer tasks. Overall, this pump is a versatile solution that ensures hygienic and efficient production processes.

Easy maintenance

Maintain-in-Place without removal of piping or dismantling the entire pump

Cost-effective

Significant reduction in maintenance costs. No need for disassembling joints with laborious assembly and dismantling of retaining straps. Simple removal of clogged fibrous material

Preventive

No unscheduled downtime thanks to simplified preventive inspection and maintenance of the joints

High system availability

Fast maintenance of rotor- and drive-side components for trouble-free operation

Comments

Post a Comment