Tarby Pumps

Tarby Pumps-A Comprehensive Overview

Introduction

Tarby pumps are widely recognized for their exceptional performance and durability. This article provides a comprehensive overview of Tarby pumps, their features, applications, and advantages.

Features of Tarby Pumps

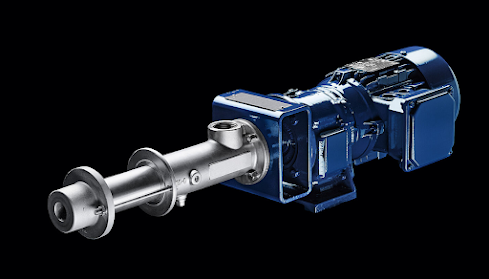

Tarby pumps are known for their robust construction and high-quality materials. They consist of a progressive cavity pump that uses a rotor and stator to move fluid through the pump. The design of Tarby pumps ensures consistent flow rates and low pulsation, making them ideal for handling sensitive fluids or those with high solids content.

Applications of Tarby Pumps

Tarby pumps have found widespread use in various industries, including wastewater treatment, oil and gas, chemical processing, and food and beverage. Their unique design allows them to handle viscous fluids, abrasive slurries, and delicate emulsions with ease.

Advantages of Tarby Pumps

Tarby pumps offer numerous advantages over other types of pumps. They are highly efficient, provide consistent flow, and can handle a wide range of fluids, making them versatile. Additionally, they require minimal maintenance, ensuring long-term reliability and reduced operating costs.

Maintenance and Repair of Tarby Pumps

Although Tarby pumps require minimal maintenance, regular checks are necessary to ensure optimal performance. Routine inspections include checking for wear on the rotor and stator and maintaining proper lubrication. If repairs are necessary, Tarby pumps are designed to be easily disassembled and reassembled, simplifying the repair process.

Conclusion

Tarby pumps are among the most reliable and versatile pumps available in the market. They have revolutionized various industries by providing exceptional performance and durability. With minimal maintenance requirements and easy-to-manage repairs, Tarby pumps offer a practical solution to a wide range of pumping needs.

Comments

Post a Comment