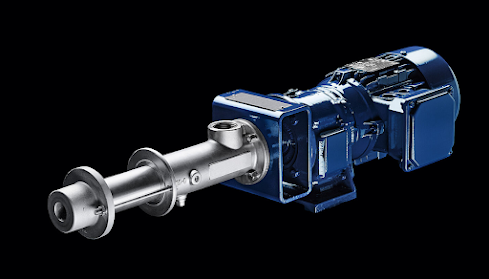

Progressive Cavity Pump Diagram

Progressive Cavity Pump Diagram

Introduction

A progressive cavity pump is a type of positive displacement pump that is used to move fluids through a process system. It is also known as a helical rotor pump or a Moyno pump. The pump consists of two main components: a stator and a rotor. In this article, we will discuss the progressive cavity pump diagram in detail.

The Stator

The stator of a progressive cavity pump is a stationary housing that is made up of a rubber or elastomeric material. The stator contains a helical cavity that matches the shape of the rotor. As the rotor turns within the stator, it creates a series of sealed cavities, which move the fluid through the pump. The stator is responsible for providing the required sealing between the suction and discharge sides of the pump.

The Rotor

The rotor of a progressive cavity pump is a helical screw-like spindle that fits inside the stator. The rotor has one less thread than the stator and rotates eccentrically causing a series of sealed chambers to form between the rotor surface and the stator. These sealed chambers are responsible for moving the fluid through the pump. The rotation of the rotor compresses the fluid, creating pressure, and pushing it towards the outlet of the pump.

Sealing

The sealing mechanism in a progressive cavity pump is created by the tight fit between the stator and rotor. This creates a set of seals that prevent the fluid from flowing back from the discharge side to the suction side. Additionally, the stator provides the support required to maintain the alignment of the rotor and stator.

Suction and Discharge Ports

The suction and discharge ports are located at the opposite ends of the pump. The suction port is where the fluid enters the pump, while the discharge port is where the fluid leaves the pump. The suction and discharge pressure difference is what drives the fluid through the pump.

Applications

Progressive cavity pumps are used in a wide range of applications, including food processing, wastewater treatment, chemical processing, and oil and gas production. The pump's ability to handle viscous fluids, abrasive slurries, and shear-sensitive materials has made it a popular choice for many industries.

Conclusion

A progressive cavity pump is an essential component in many industrial processes. Understanding the progressive cavity pump diagram can help you understand how the pump works and how it can be used effectively in different applications.

Comments

Post a Comment