Progressive Cavity Pump Design

Designing a Progressive Cavity Pump: An Overview

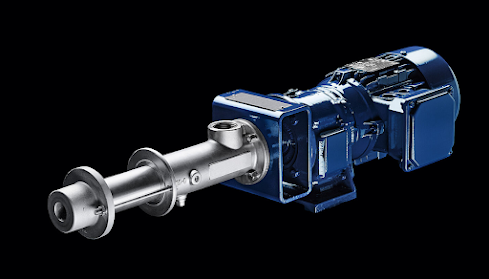

A progressive cavity pump, also known as a helical rotor pump or a Moineau pump, is a type of positive displacement pump that is widely used in various industries. The pump features a unique design that enables it to handle viscous and abrasive fluids with ease. In this article, we will take a closer look at the key aspects of designing a progressive cavity pump.

Understanding the Working Principle of a Progressive Cavity Pump

The first step in designing a progressive cavity pump is to understand its working principle. A progressive cavity pump consists of two main components: a rotating helical rotor and a stationary stator. As the rotor rotates inside the stator, cavities are created that move along the length of the stator. This creates a pumping action that draws fluid into the pump and moves it through the stator and out of the discharge port.

FDetermining the Pumping Capacity and Flow Rate

One of the key considerations when designing a progressive cavity pump is determining its pumping capacity and flow rate. This involves understanding the viscosity and density of the fluid being pumped, as well as the desired flow rate and pressure. The size and shape of the rotor and stator can be adjusted to achieve the desired performance characteristics.

Choosing the Right Materials

Another important aspect of designing a progressive cavity pump is choosing the right materials for the rotor and stator. The materials must be able to withstand the abrasive and corrosive nature of the fluid being pumped. Common materials used for rotors and stators include stainless steel, rubber, and various types of elastomers.

Addressing Wear and Tear

Progressive cavity pumps are subject to wear and tear due to the abrasive nature of the fluids they handle. As such, it is important to address wear and tear in the design process. This can involve using materials that are more resistant to wear, as well as designing the pump with replaceable parts that can be easily replaced when they become worn.

Accounting for Temperature and Pressure

it is important to account for temperature and pressure when designing a progressive cavity pump. As fluid temperatures and pressures increase, the performance of the pump can be affected. Special attention must be paid to the materials used, as well as the design of the rotor and stator, to ensure that the pump can operate effectively under a range of conditions.

Conclusion

In conclusion, designing a progressive cavity pump requires careful consideration of a range of factors. By understanding the working principle of the pump, determining the pumping capacity and flow rate, choosing the right materials, addressing wear and tear, and accounting for temperature and pressure, engineers can create pumps that are reliable, efficient, and effective for a wide range of applications.

Comments

Post a Comment