Netzsch NEMO® L.Cap Progressing Cavity Pumps

Netzsch NEMO® L.Cap Progressing Cavity Pumps

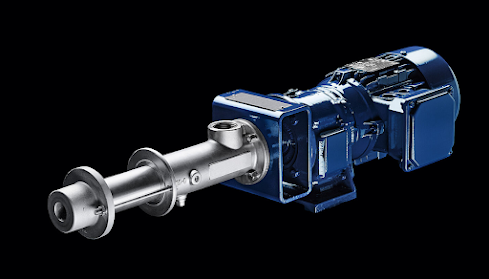

NEMO® L.Cap Progressing Cavity Pumps

High flow rates and high pressure in the oil and gas industry: This is what the NEMO® L.Cap progressing cavity pump offers you. It is available in single, twin, and vertical versions and is ideally suited for various applications .

The Description of NEMO® L.Cap Progressing Cavity Pumps

The NEMO® L.Cap is particularly suitable for high pressures and flow rates in the oil and gas industry. The innovative design of the NEMO® L.Cap allows you to pump up to 1000 m³/h at pressures of up to 24 bar without any problems. This means that nothing stands in the way of efficient pumping of oil, gas and water mixtures containing high quantities of solids. Crude oil, production water, seawater or muddy seawater can be pumped over long distances without any problems. The NEMO® L.Cap meets the requirements of API 676 3rd edition and also those of NACE MR-0-175. The model is available as a single, twin, and vertical version.

High-Performance Pumping for Challenging Substances with Netzsch NEMO® L.Cap Pumps

The Netzsch NEMO® L.Cap progressing pumps are commonly used in industrial applications where a reliable and consistent flow of viscous or abrasive materials is required. These high-performance pumps offer excellent pumping capabilities for challenging substances, such as sludge, slurries, and chemicals, making them popular choices in industries such as wastewater treatment, food processing, and oil and gas production.

Robust Design and Customizable Features of Netzsch NEMO® L.Cap Progressing Cavity Pumps

The Netzsch NEMO® L.Cap progressing cavity pumps offer a range of features that make them ideal for challenging pumping applications. These pumps feature a robust, compact design that is capable of handling a wide range of viscous and abrasive materials while providing consistent flow rates. Other key features include a sturdy rotor-stator construction, a low pulsation flow, and a smooth, gentle pumping action that minimizes product damage. Additionally, these pumps are highly customizable, allowing users to select from a variety of materials and configurations to meet their specific application requirements.

Comments

Post a Comment