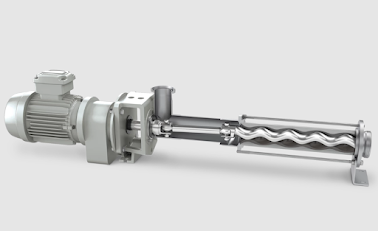

Hopper Progressive Cavity Pump in Bearing Block

Hopper Progressive Cavity Pump in Bearing Block What is a Open hopper feed progressive cavity pump in bearing block design Open hopper feed progressive cavity pump in bearing block design is a kind of progressive cavity pump which also has a enlarged rectangular hopper, coupling rod with auger and force-feed chamber with taper. Because it is a bearing block design, it can cooperate with a variety of drivers. Its structure is stable and can bear more pressure and torsion. The feature of the Open hopper feed progressive cavity pump Open hopper cavity pump larger hopper, larger capacity Special coupling rod with auger has greater torque and stronger propulsion The large force-feed chamber with taper is more conducive to the transportation of materials Bearing block design, more diverse driving methods The structure is stable and can withstand worse working conditions Easy to disassemble and maintain Continuous low pulsation transportation, not affected by pressure and viscosi...